A printed circuit board, or PCB, is used to mechanically support and electrically connect electronic components using conductive pathways, or traces, etched from copper sheets laminated non-conductive substrate onto a substrate.Alternative names are Printed Wiring Board (PWB) and etched wiring board. A PCB populated with electronic components is a printed circuit assembly (PCA), also known as a printed circuit board assembly (PCBA).

PCBs are rugged, inexpensive, and can be highly reliable. They require much more layout effort and higher initial cost than either wire-wrapped or point-to-point constructed circuits, but are much cheaper, faster, and consistent in high volume production. Much of the electronics industry’s PCB design, assembly, and quality control need are set by standards that are published by IPC organization.

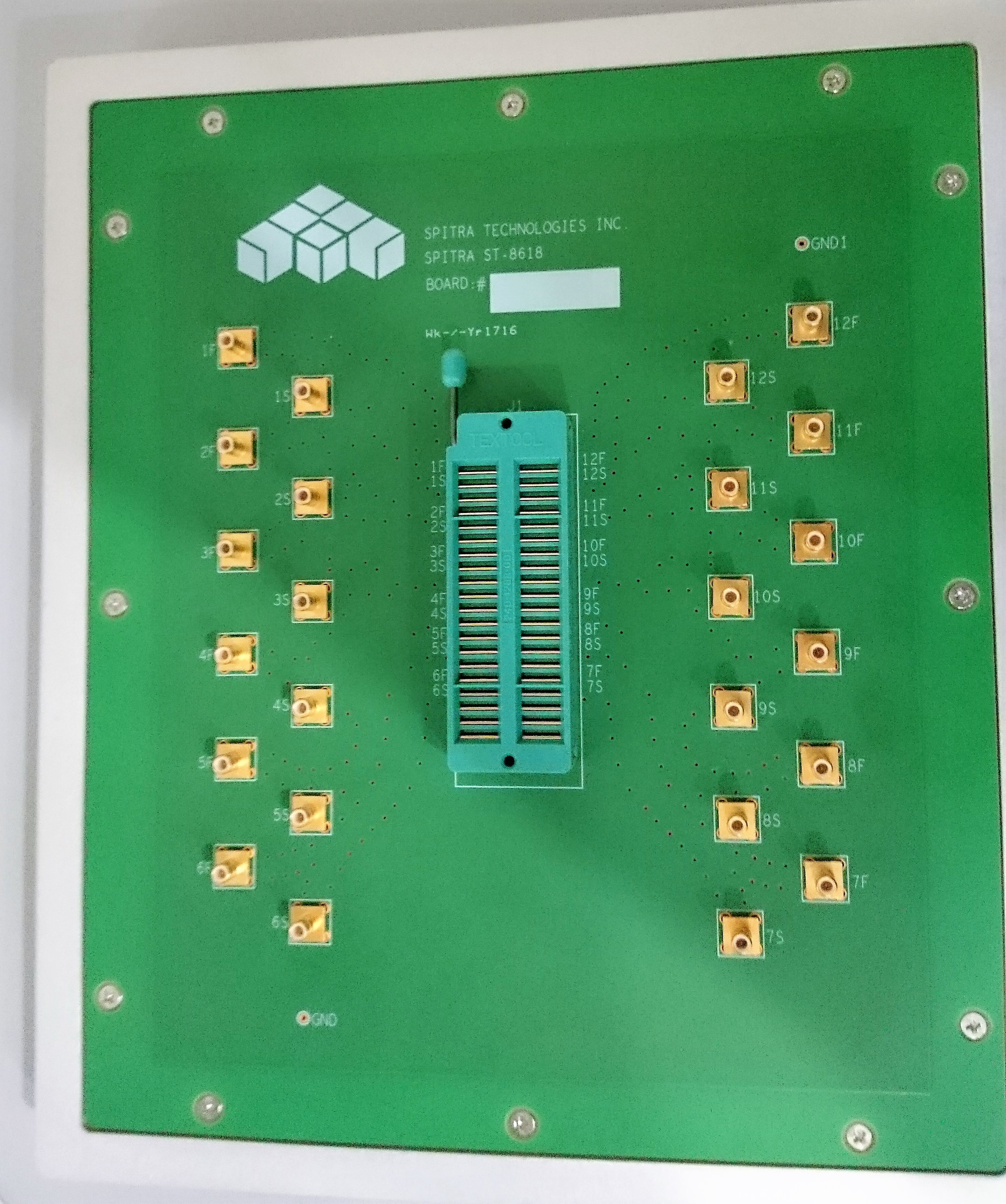

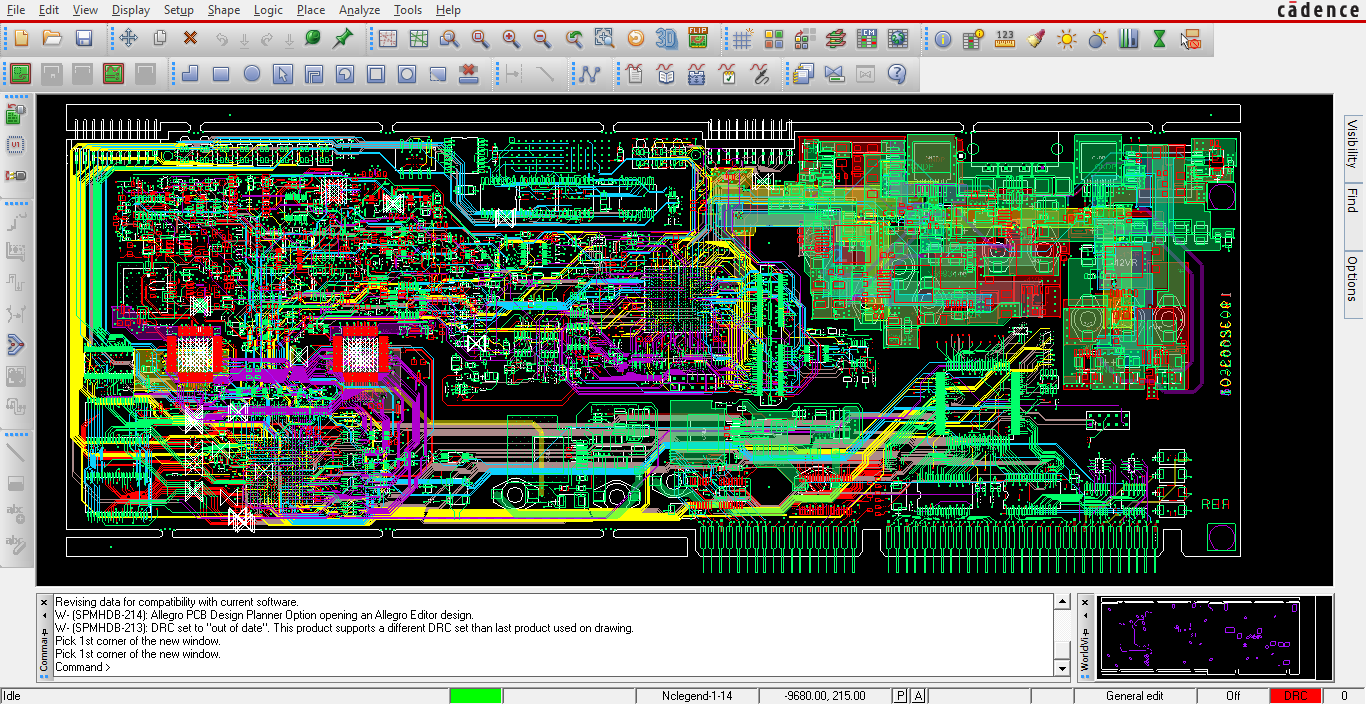

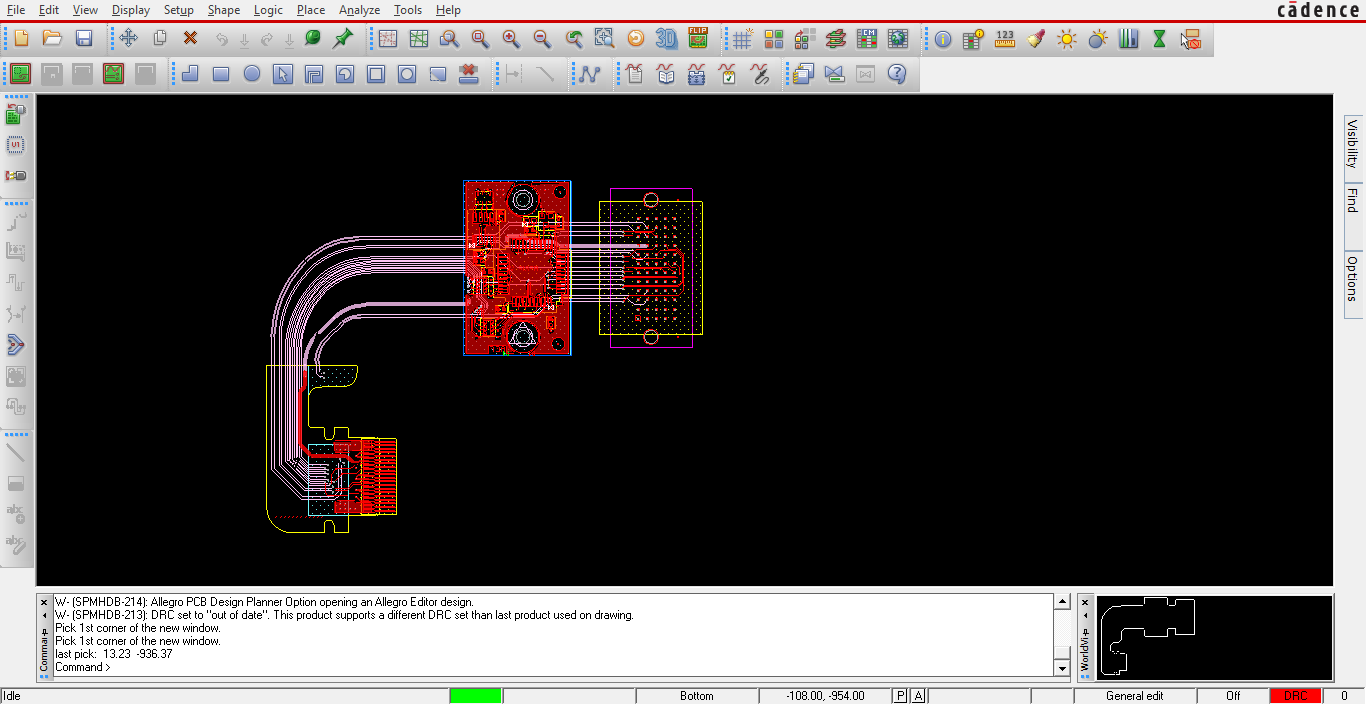

We are IPC Certified (CID) and our experience includes single-sided, double-sided, and multilayer boards, through hole and SMT, high speed design, test boards, flex circuits, and we supply all relevant documentation, including schematics, assembly and fabrication drawings.

We are knowledgeable on DFM (Design for Manufacturing) issues and rules, thus manufacturability is applied into all our designs, keeping your cost down.

We are equipped with the latest advance software tools to execute your specific needs and requirements fast.

PCB material, size and stackup selection, placement of the components, decoupling and bypassing, routing techniques for high speed and critical nets, power – ground planes etc – we will address all these issues during the transition from the schematic to the PCB layout.

Flexible PCBs are light in weight and easy to assemble. We are experienced in designing flexible circuit board which adhere all the manufacturing requirements and same time to meet your specifications.

- PCB Layout

- Schematics Diagrams

- Gerber/Artwork drawings

- Reverse Engineering

- Gerber Editing

Our Custom PCBs

.jpg)